CNC machining can be defined as automatically and digitally controlled machining processes. Main machining processes include:

· Milling, where the spindle rotates removing material.

· Turning, where the cylindrical workpiece rotates while spindle is fixed removing the material

· Drilling, where a hole is cut into the workpiece

· Grinding, where a rolling, abrasive wheel removes light amounts of material

· Sawing where material is cut (into parts) with a blade.

· Finishing operations (1-Filing that is about light amounts of material removing, combining grinding and sawing and is used mostly in deburring. 2-Polishing and brushing, where a smooth or shiny surface is created with abrasive process.)

·

Available CNC machining services

| Name | Description |

|---|---|

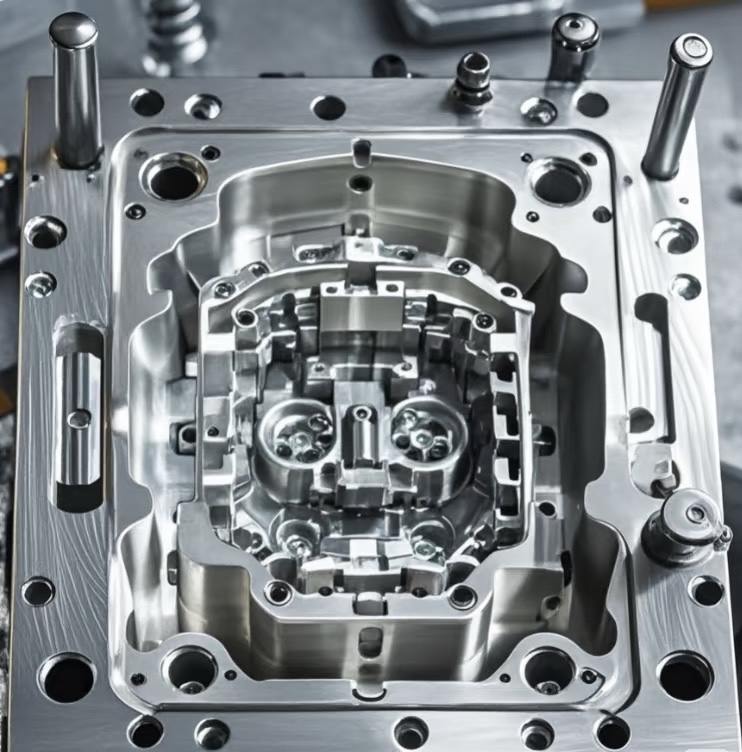

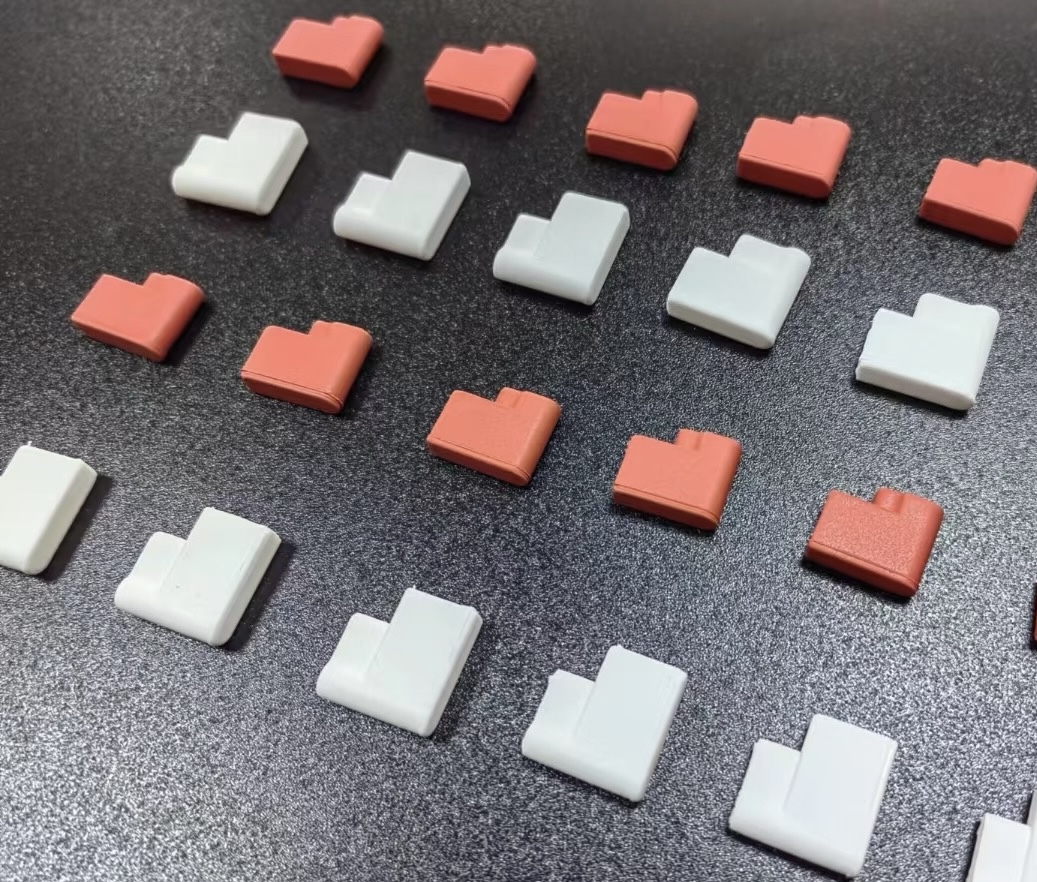

| CNC Milling service | CNC milling is a subtractive manufacturing process that rapidly removes material from metal or plastic blocks to produce precision parts with tight tolerances. |

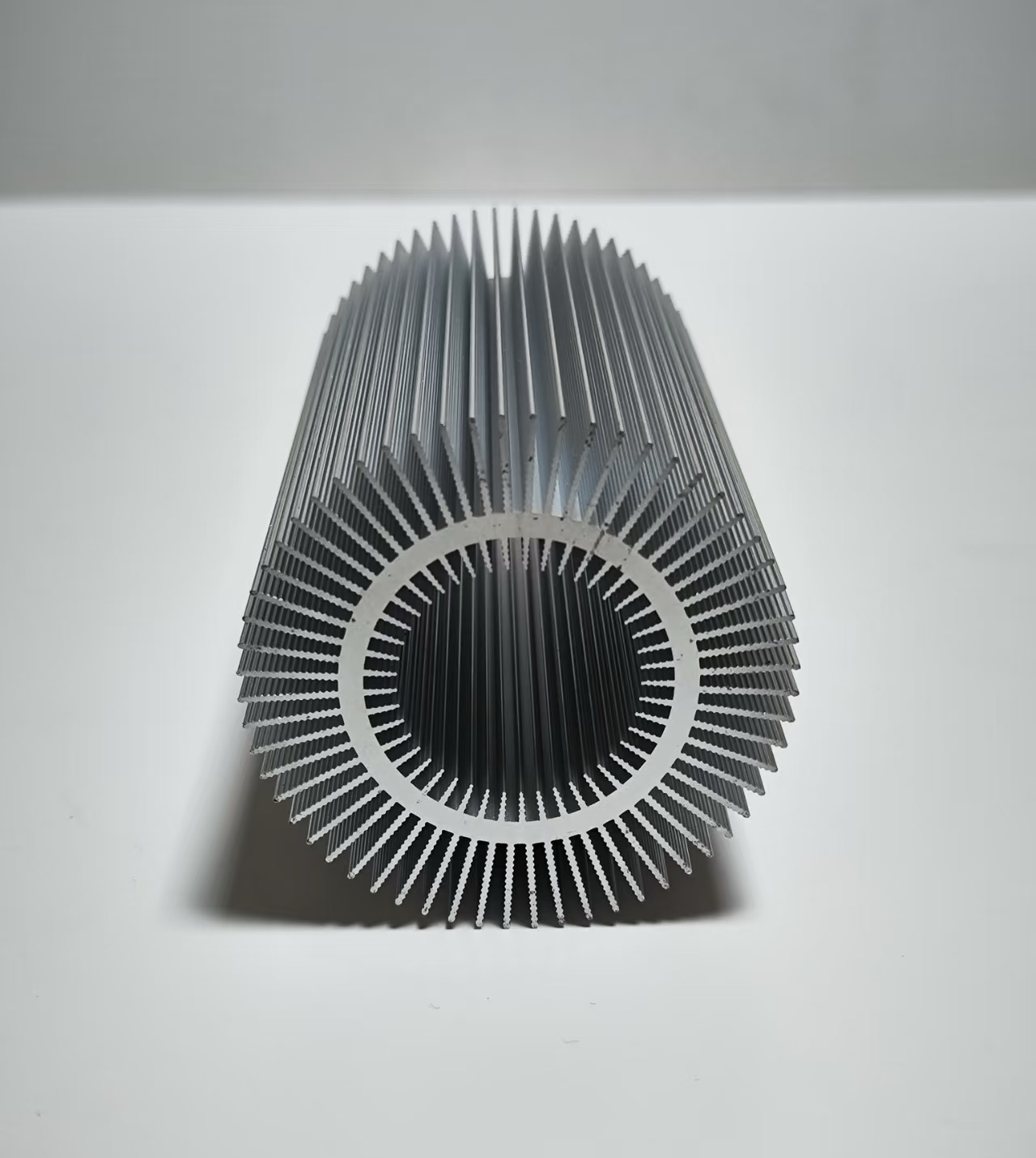

| CNC Turning service | CNC turning produces parts with cylindrical features by removing material from metal or plastic rods using cutters, center drills or live tooling. |

| 5-axis CNC machining | 5-axis CNC machines can produce parts with complex geometries and increase productivity by minimizing the number of machine setups. |

Available materials for CNC machining

| Plastics | Aluminum | Stainless steel | Other steels | Other metal |

|---|---|---|---|---|

| ABS | 6061-T6 | 303 | Mild steel 1018 | Brass C360 |

| Nylon 6 | 6082 | 304 | Mild steel 1045 | Copper C101 |

| POM (Delrin/Acetal) | 7075 | 316 | Mild steel A36 | Copper C110 |

| PC (Polycarbonate) | 5083 | 2205 Duplex | Alloy steel 4140 | Titanium Grade 2 |

| PVC | 5052 | 17-4 | Alloy steel 4340 | Zinc alloy |

| HDPE | 6063-T5 | 420 | Tool steel O1 | Magnesium alloy AZ91D |

| PTFE (Teflon) | 7050 | Tool Steel A2 | ||

| PEEK | Tool Steel D2 | |||

| Nylon 15%GF/30%GF | Tool Steel S7 | |||

| Acrylic (PMMA) |

More materials and heat treatments are available upon request

Tolerances

The table below summarizes the standard tolerances of the parts produced by us. Tolerances up to .0008" (0.020mm) are available upon request.

| Part size / Dimension | Tolerance | Angularity |

|---|---|---|

| < 12'' (300 mm) | ± .005'' (0.125 mm) | ± 0.5° |

| < 24'' (600 mm) | ± .010'' (0.250 mm) | ± 1.0° |

| < 36'' (900 mm) | ± 1/64'' (0.400 mm) | ± 1.0° |